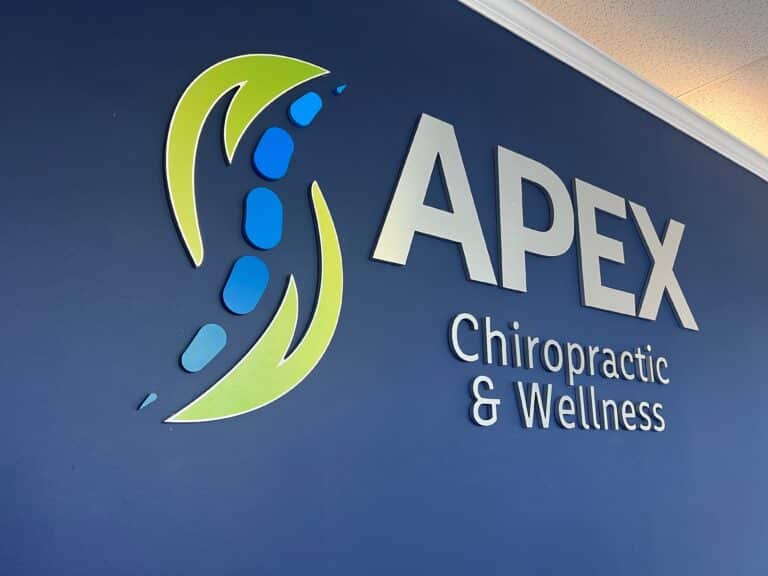

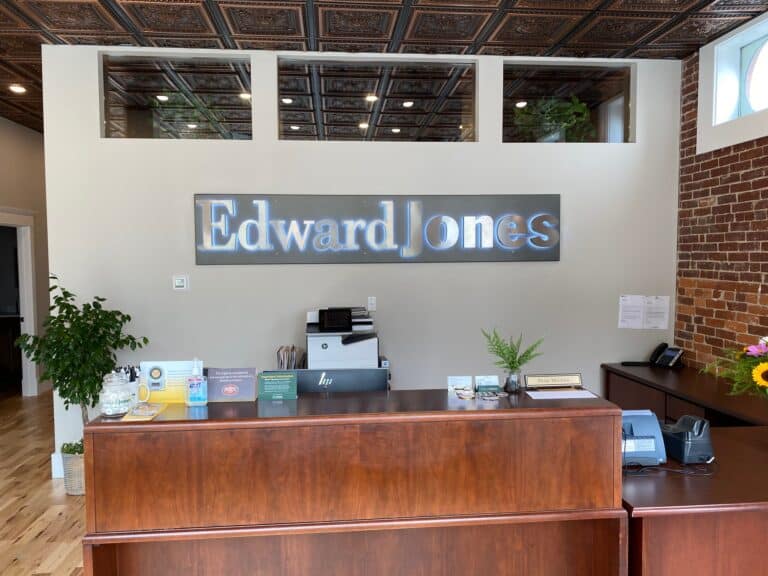

Metal Logos takes a hands-on approach when it comes to making your custom metal sign. If you can dream it, we can make it. Here are the ways, we at Metal Logos create custom metal logos and signs. Once Metal Logos has the image you are looking to create for your signage, we can give you several options in cost using different materials.

Metal Logos takes a hands-on approach when it comes to making your custom metal sign. If you can dream it, we can make it. Here are the ways, we at Metal Logos create custom metal logos and signs. Once Metal Logos has the image you are looking to create for your signage, we can give you several options in cost using different materials.

CNC Machining

One example of how metal signs are made is CNC, which is short for computer numeric controlled. This precision machinery cuts, grinds or drills into substrate.

We make Custom Metal Signs and Logos for your business. This manufacturing process uses pre-programmed computer software to direct the movement of the machinery. With CNC machining, three-dimensional cutting jobs can be easily achieved.

Laser Cutting

Laser cutters can cut and engrave designs from flat sheet materials such as metal and acrylic. Depending on the thickness of the material, the results can be somewhat three-dimensional.

Laser cutting provides many options for sign making, from flat panel cut outs to individual letters. We can even make backlit or edge-lit designs using laser cutting.

Laser engraving works without touching the substrate and picks up subtle details in a design. It can be used on metal, as well as other types of materials.

Water Jet Cutting

A water jet cutter is an industrial tool capable of cutting a wide variety of substrate using a very high-pressure jet of water, or a mixture of water and along with an abrasive element.

Water jet cutting is a cost-effective way to cut 2D shapes from a very wide range of substrate with no tooling costs. It usually eliminates the need for secondary finishing processes.

Using a water jet, we can cut single or multi-layer materials from as thin as .001 inch to as thick as several inches. Water jet cutting is yet another example of how metal signs are made.

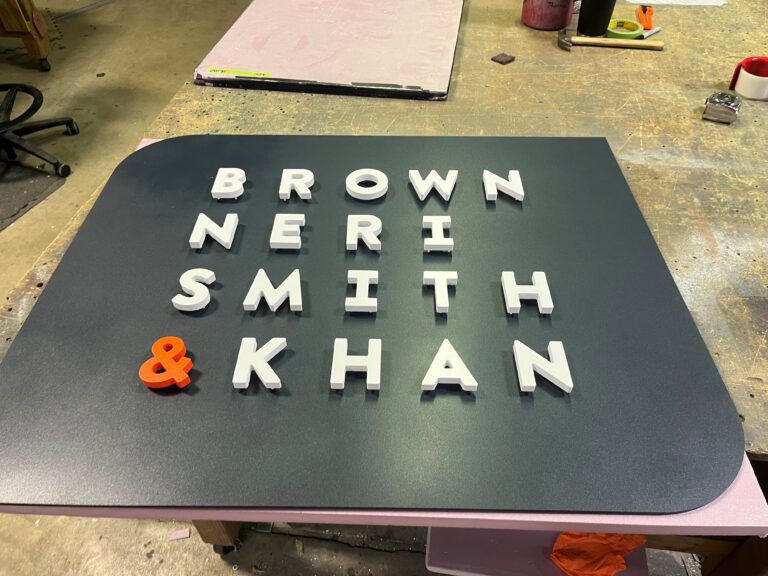

Quality Custom Metal Business Signs and Logos Flatbed Printing

Flatbed digital printers, also known as flatbed UV printers, are characterized by a flat surface on which a material is placed to be printed on. The machine uses a multi-axis computer control system. The design picture or photo is entered into the computer and then printed on the substrate directly.

This type of flatbed printing can be used on metal, acrylic, PVC, ABS and many other substrates.

Die-Cut Printing

In the printing world, a die refers to a thin, razor-sharp steel blade that has been formed into a specific shape or pattern. Dies are sort of like heavy-duty cookie cutters that are used to cut substrates into various shapes. This allows Metal Logos to jigsaw cut and inlay different colors of metal into a Die-Cut design, if needed.

Like other forms of printing, die-cutting is an automated process that allows multiple pieces of the same shape to be created efficiently and uniformly. There is a selection of standard dies available for common cuts and shapes but custom dies can also be created for specific designs. Die-cutting is a very versatile example of how metal signs are made. A die can be used to shape the entire perimeter of a sign, or to just shape one corner or edge. It can also cut shapes out of the center of a sign.